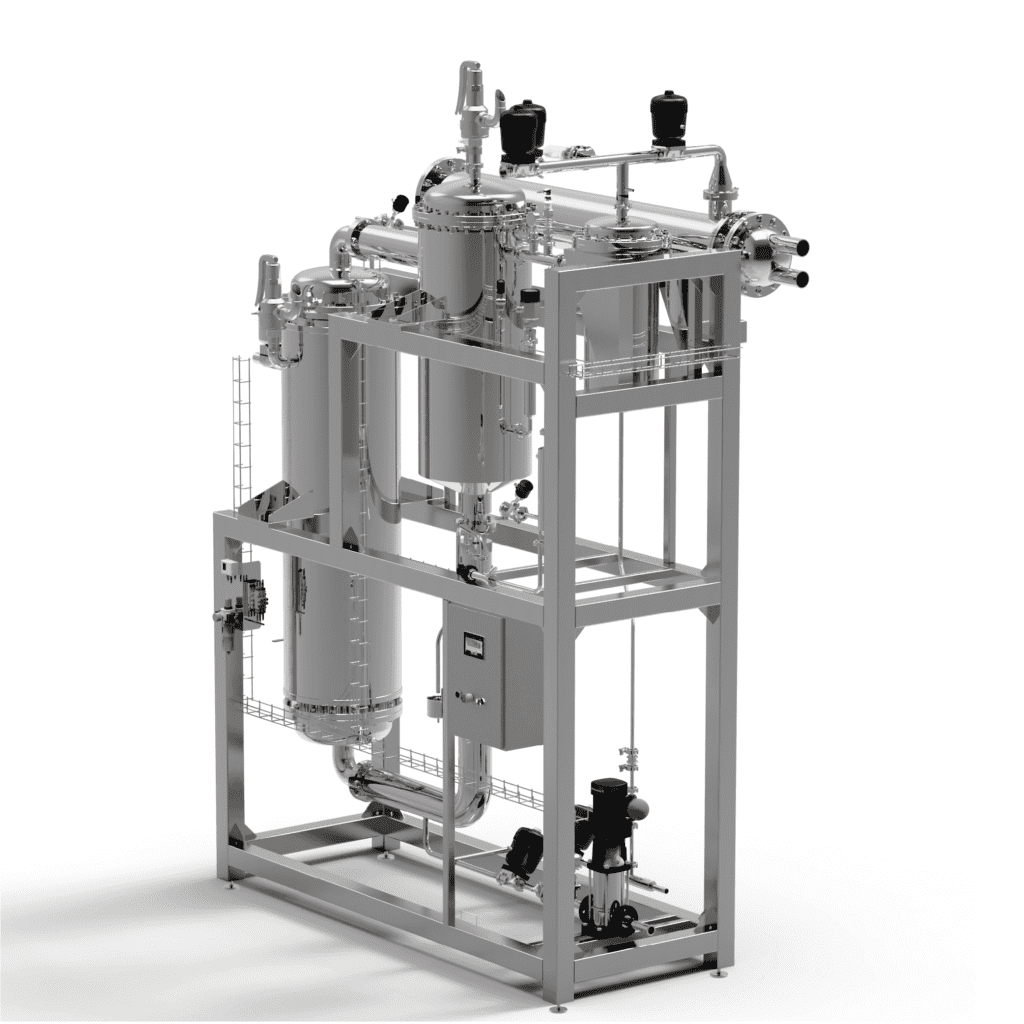

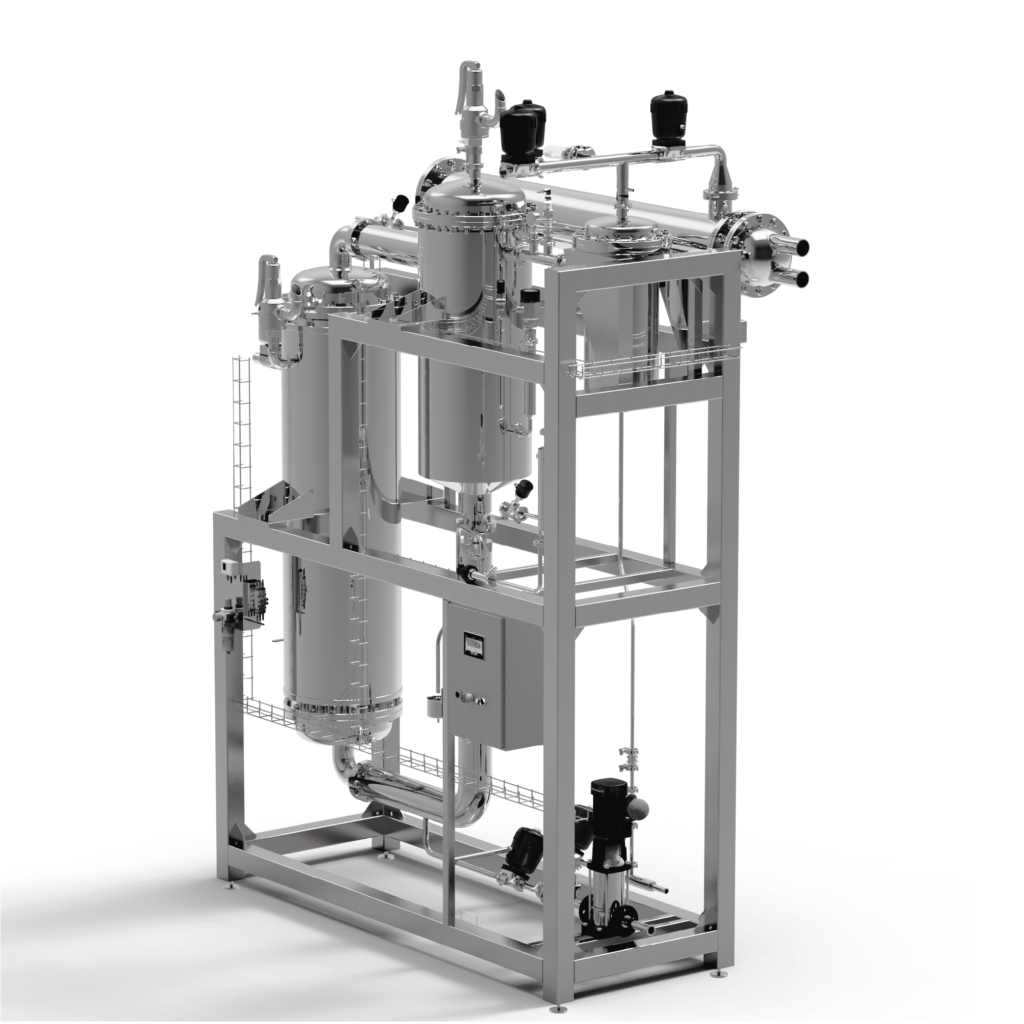

Water Distillers

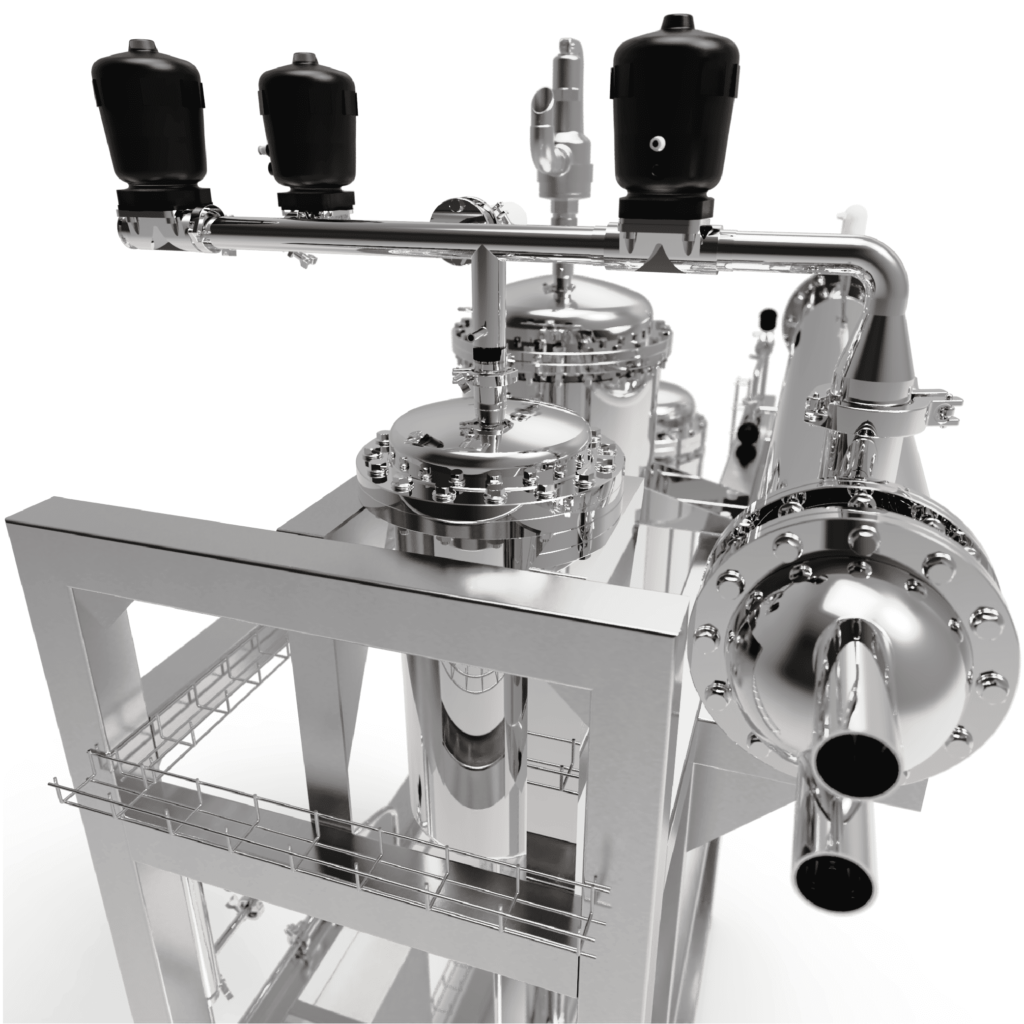

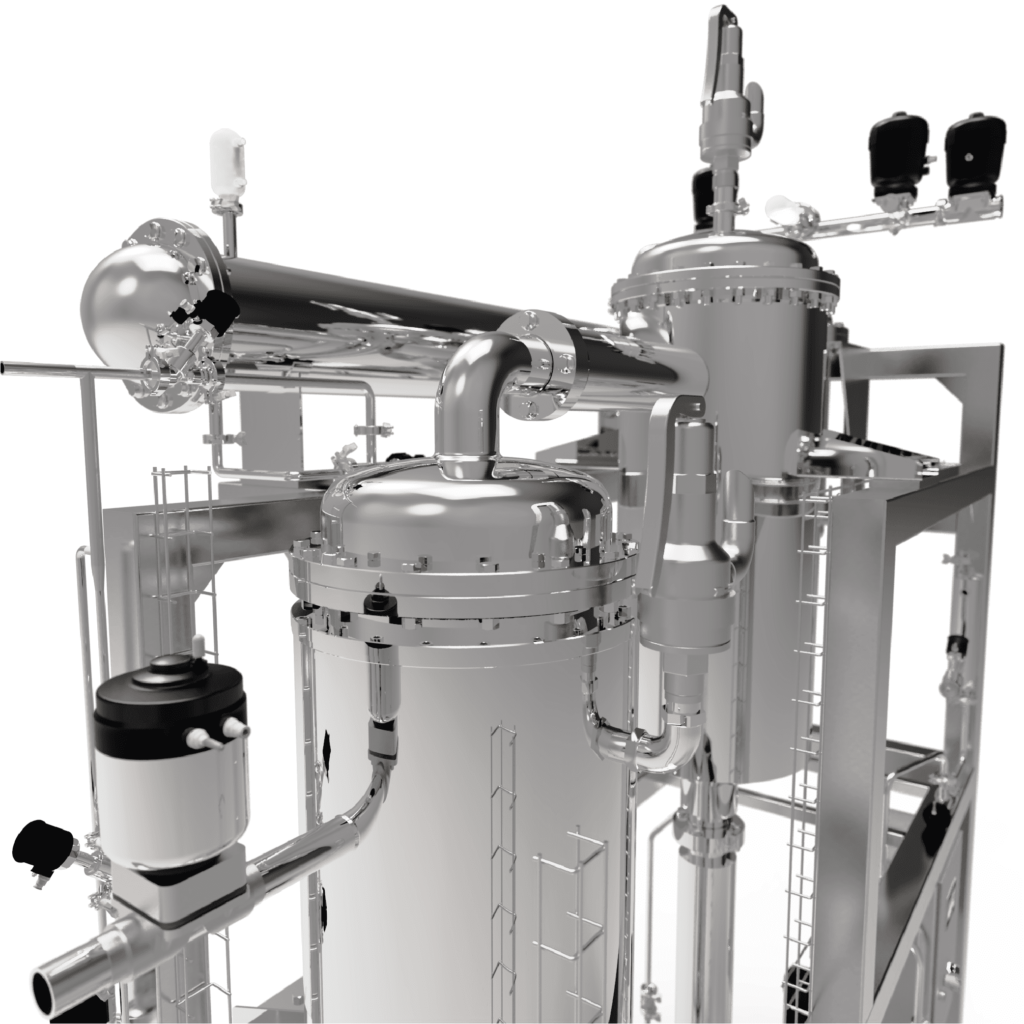

Designed to obtain of WFI quality water. It is a single effect work system based on the condensation of apyrogenic steam.

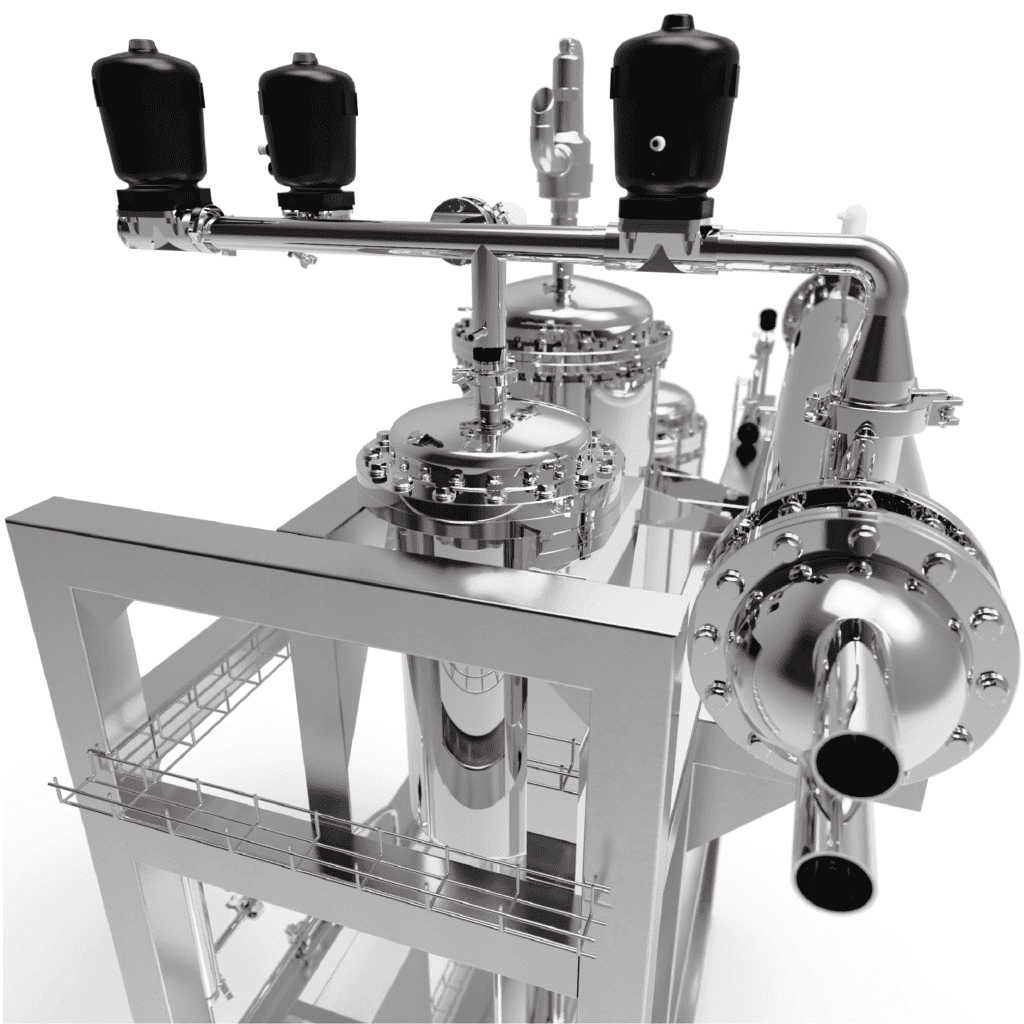

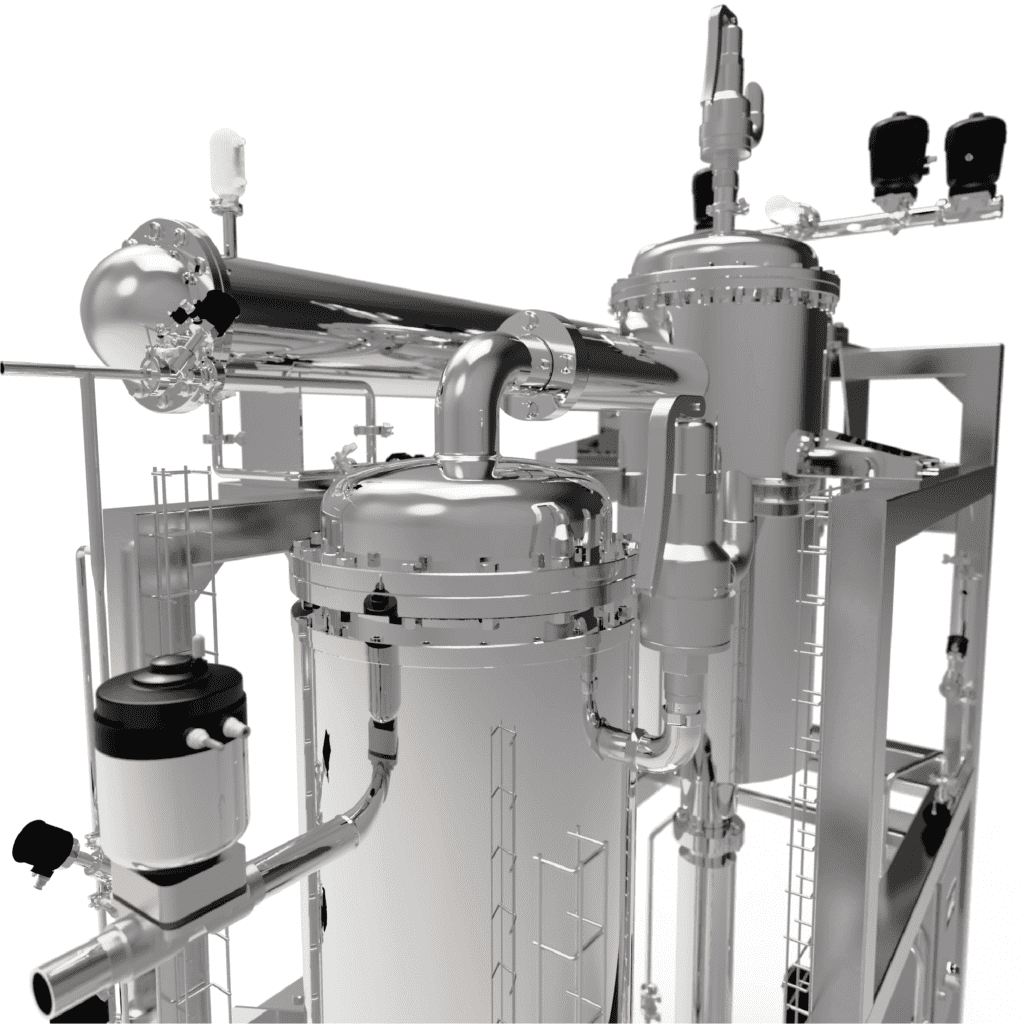

Steam is produced in a shell and tube heat exchanger entirely made of 316L stainless steel with sanitary finish. The heat exchanger is DTS (Double Tube Sheet) type and it is built as per the ASME code, and GMP compliant.

The droplet separator consists of a cyclonic filter which, using centrifugal force, guarantees absolutely the steam purity, removing condensates and pyrogens.

WFI water is obtained from apyrogenic steam condensation in a shell and tube heat exchanger entirely made of 316L stainless steel with sanitary finish. The condenser is DTS (Double Tube Sheet) type and it is built as per the ASME code, and GMP compliant.

Based on the volume of WFI water produced by the equipment, it may be heated electrically or by means of industrial steam. In the case of electrical equipment, the heating system is fitted with sanitary resistors made of 316L stainless steel.

Microprocessed command with industrial PLC and HMI touch screen, Title 21 CFR Part 11 compliant, which guarantees data traceability. There are different access levels through passwords to set the different parameters for each cycle.

In-line conductivity meter.

WFI water disposal.

Feed tank.

PW water sampling.

WFI water sampling.

Storage tank.

| Distillers | Capacity L/hour |

|---|---|

| DH 50 *Electrically Heated. | 50 |

| DH 100 | 100 |

| DH 200 | 200 |

| DH 300 | 300 |

| DH 400 | 400 |

| DH 500 | 500 |

| DH 600 | 600 |

| DH 700 | 700 |

| DH 800 | 800 |

| DH 900 | 900 |

| DH 1000 | 1000 |