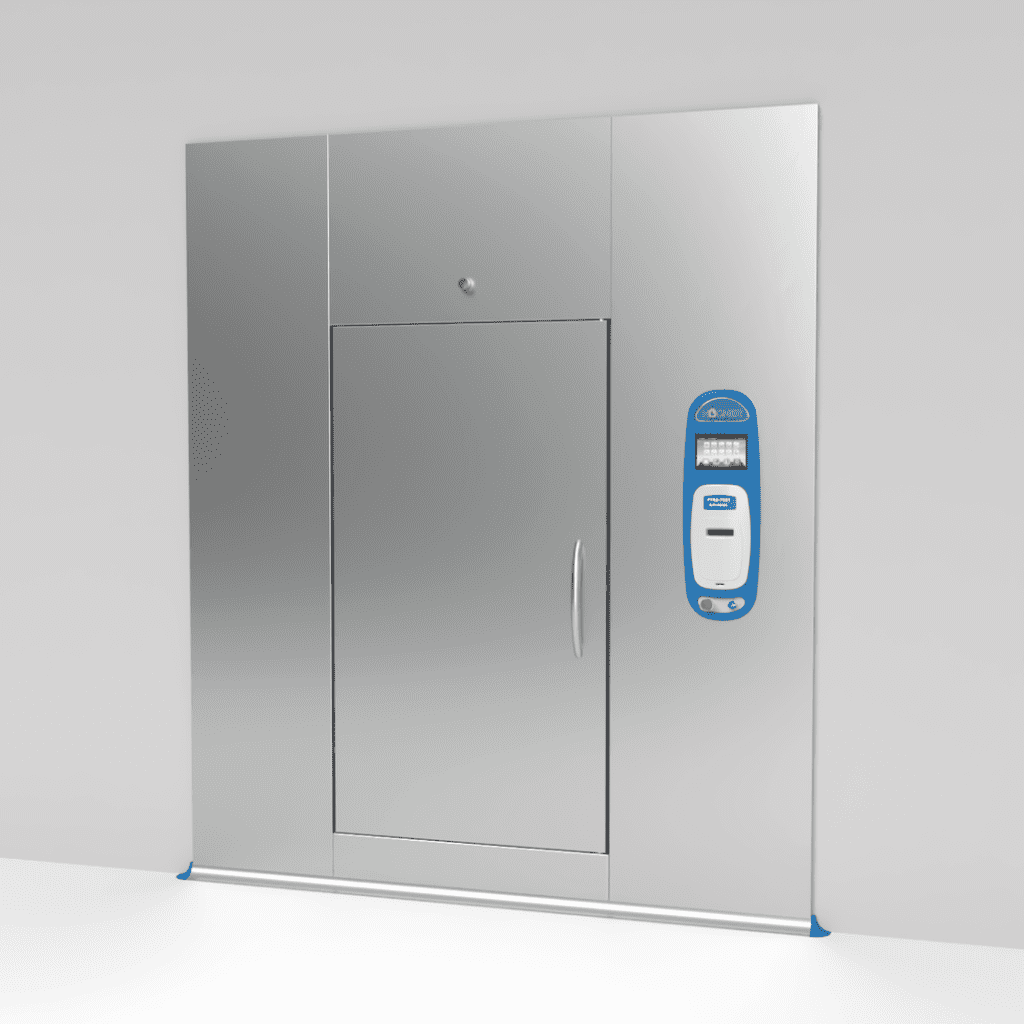

Depyrogenation Oven

Especially designed to depyrogenate glass. Fitted with absolute HEPA filters and forced cooling.

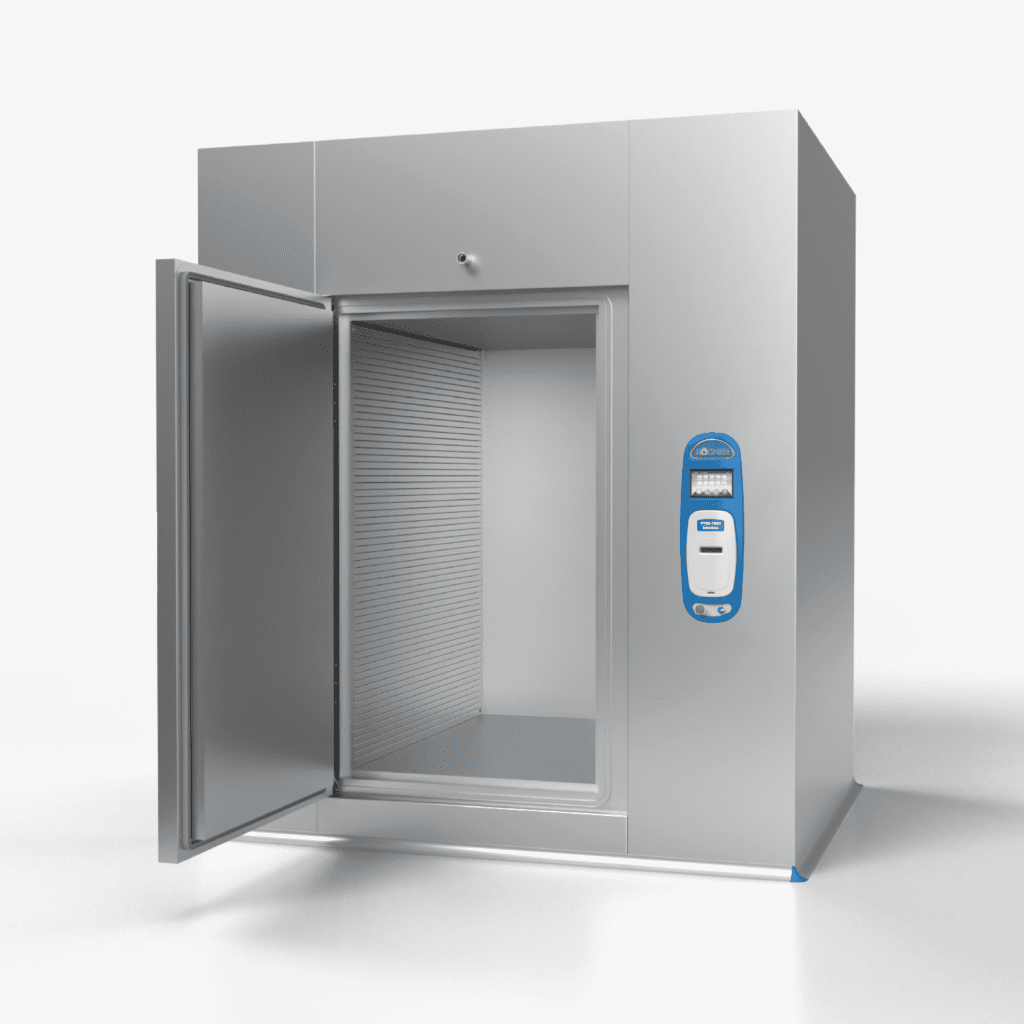

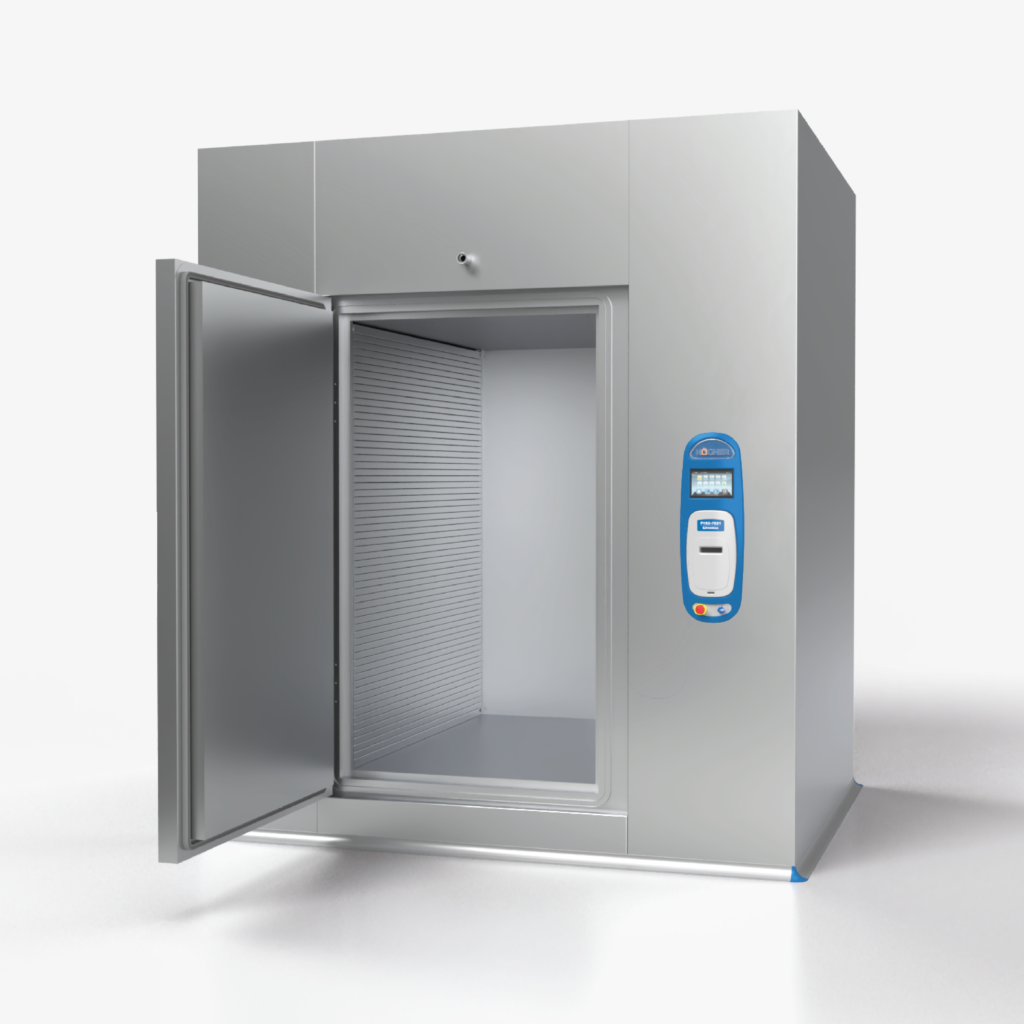

Chamber and doors are made of 316L stainless steel. Chamber is completely welded, which guarantees its airtightness. The whole set is thermally insulated.

Ovens are built with an internal side of HEPA filters, especially designed for high temperature. The whole amount of air recirculating during the process is filtered before coming in contact with the product. The air outlet is fitted with an HEPA filter for high temperature, which avoids any potential cross-contamination.

Microprocessed command with industrial PLC and HMI touch screen, Title 21 CFR Part 11 compliant, which guarantees data traceability. There are different access levels through passwords to set the different parameters for each cycle.

An alphanumeric printer prints all process data and variables.

The cooling temperature of the load can be programmed by the system. Rapid cooling is achieved by means of a heat exchanger where cold water circulates.

Composed of loading trolleys and transfer trolleys to place and transfer the materials to be depyrogenated. In the case of glass vials or ampoules, trolleys are designed to allow loading of trays and to optimize the useful capacity of the chamber. Every loading system is analyzed and designed based on the different kind of materials to be processed, this being a key element in the design of an oven.

| Models | Capacity (L) |

|---|---|

| PYRO 1 | 850 lts |

| PYRO 2 | 1000 lts |

| PYRO 3 | 1560 lts |

| PYRO 4 | 2050 lts |

| PYRO 5 | 2500 lts |

| PYRO 5 | 3060 lts |

| PYRO 5 | 3500 lts |

*We manufacture customized chambers for capacity greater than 5,000 L.